- Bayan Lepas, Penang, Malaysia

- techsupport@tascontech.com

- Office Hour : 08:00am - 6:00pm

With 20 Years of repair experience, our expertise in repairing:

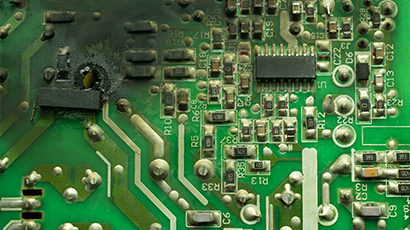

Identifying blown components involve a full visual inspection of the PCB under the microscope. Once the blown component is identified, the component is then replaced by referring to a circuit diagram or similar PCB. Sometimes, a reconstruction of the trace may be necessary depending on the severity of the damage.

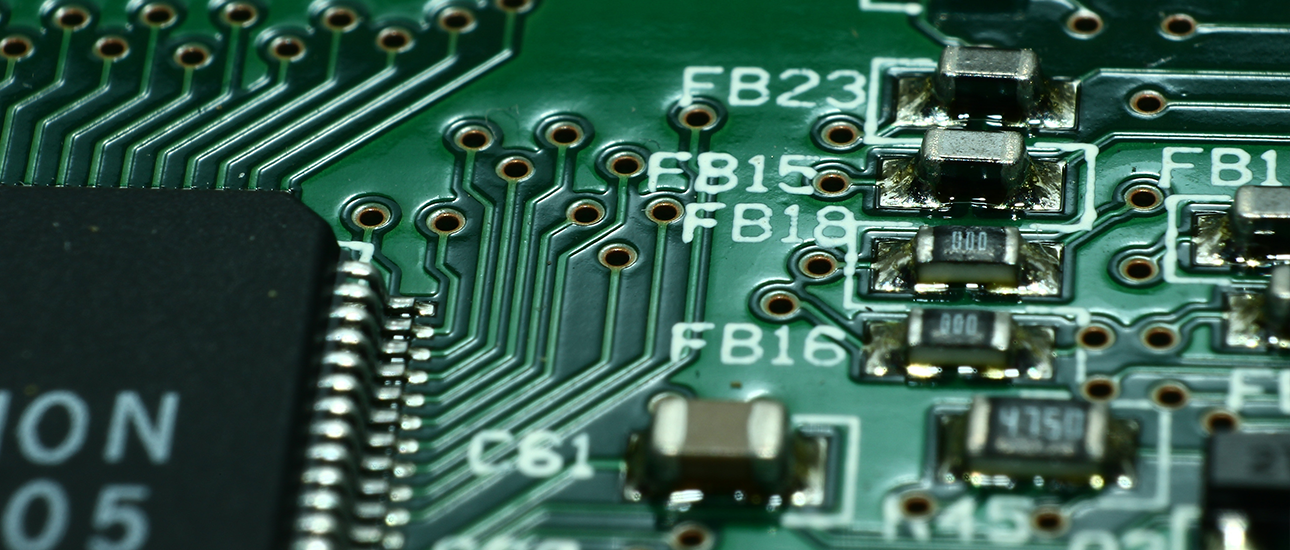

A lifted pad on PCB is a pad that has detached from the surface of the PCB. This causes the connection to be broken or intermittent. Once the lifted trace is identified, rework can be done by removing the loose trace, and replacing it with a jumper wire or using a trace pen

Solution Analysts welcomes you to try our services. We invest the same time and energy in Pilot Projects as real projects. We have always succeeded in continuing the relationship after demonstration of ability in a pilot project different from prototypes.

Solution Analysts welcomes you to try our services. We invest the same time and energy in Pilot Projects as real projects. We have always succeeded in continuing the relationship after demonstration of ability in a pilot project different from prototypes.

Solution Analysts welcomes you to try our services. We invest the same time and energy in Pilot Projects as real projects. We have always succeeded in continuing the relationship after demonstration of ability in a pilot project different from prototypes.

Any liquid spill can cause the PCB traces to corrode over time due to the voltage passing through them. This cause continuity problem in the PCB and thus affects the functionality of the board. Excessive humidity can also cause it to corrode. Corrosion repair involves cleaning the PCB to stop further damage, and also reconstruction of the traces and replacement of the affected components.

Ball Grid Array (BGA) chip replacements require a precise rework. A special machine with an accurate temperature controller is needed for BGA Rework to ensure that the solder balls are making good connection. The board also must be preheated to prevent any warping due to temperature differences.